DESCRIPTION

Wet Film Thickness Gauges are used to determine the thickness of liquid coatings. The measurements show an approximate information on the thickness of a liquid layer.

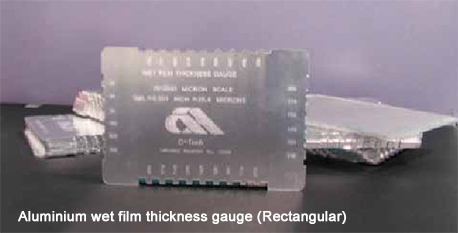

The Wet Film Thickness Gauge is available in rectangular or sexangular shape with different subdivisions of the measuring range each.

The tolerance of a particular gauge will be so certified at gauge midpoint and near its lower and upper recommended use limits and a suitable certifi cate will be included with the shipment of the gauge.

There are three levels of certifi cation available: Full Certification of both sides of the gauge for Mil and Micron, Single Scale certification in Mil, Single Scale certifi cation in Micron.

These punched aluminium combs offer the user a low cost method of measuring the wet fi lm thickness.

Features:

Solvent-proof and wear-resistant, OEM sevice is available

Wet film thickness gauge (Rectangular)

Model:WFR-A80/WFR-S80

Material:Aluminium(WFR-A80)

Material:Stainless steel (WFR-S80)

Size:83 x 58 mm2approx.

Thickness: 0.8 mm approx.

4 Measuring ranges:1 to 6 Mil (25 to 152 Micro) 7 to 12 Mil (178 to 305 Micro) 14 to 30 Mil (356 to 762 Micro) 35 to 80 Mil (889 to 2032 Micro)

Scale indications:front Mil, rear Micro

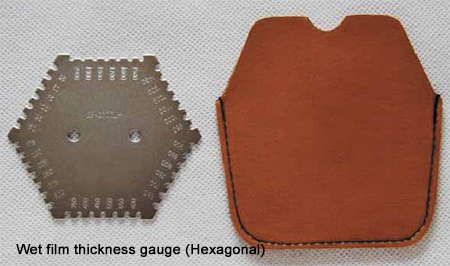

Wet film thickness gauge (Hexagonal)

Model: WFH-A113/WFH-S113

Material: Aluminium(WFH-A113)

Material: Stainless steel (WFH-S113)

Thickness: 0.8 mm approx.

Measuring ranges: 0 to 113 Mil (25 to 3000 Micro)

Scale indications: front Mil, rear Micro

Wet film thickness wheels

Model: WFW-S150

Material: Stainless steel (WFW-S150)

Measuring ranges: 0 to 150 Micro

Accuracy: 15 Micro

These punched aluminium combs offer the user a low cost method of measuring the wet fi lm thickness.

Test Method - How to use a Wet Film Comb

• For measuring, push the comb gauge perpendicularly into the film using the measuring range that corresponds to the expected fi lm thickness

• Remove the comb gauge from the coating

• The wet fi lm thickness will fall between the clearance of the shortest tab that is wet and the clearance of the next shortest dry tab